TrueSight

Full combine steering control

Equipped for

Full Combine Steering and Control

Row guidance and full steering control for a variety of machines.

Advanced Guidance and Control

TrueSight keeps you harvesting right on the row with a constant touch to the crop to overcome poor visibility, challenging terrain, and down corn. TrueSight directly controls steering valves or the steering motor for maximum control.

Row Guidance Options

Which Row Guidance Product Is Right For You?

- TrueSense improves OEM combine steering by adding sensing

- Requires OEM guidance unlock

- Single-sensor design

- Only compatible with John Deere RowSense and Lexion AutoPilot

- Replaces OEM control with advanced steering and control

- Directly controls steering valves or the steering motor

- Single-sensor design

- Wide compatibility

Key Features

Decrease Operator Fatigue

With the assurance of your corn header staying on track, you can focus on other vital settings in the cab. Capture maximum yield with less stress using row guidance.

Increase Productivity

Accurate row guidance can significantly improve material flow and feeding into the header, reducing snout damage and increasing harvest speeds in down corn.

Dual Row Sensing

Our flexible, poly sensor feels for two rows instead of the standard single-row detection. This greatly improves accuracy and response, especially in challenging conditions. Plus, the controller auto-engages, turning the system on or off, so your hand doesn't leave the hydro handle.

Control

Easy Operation and Calibration

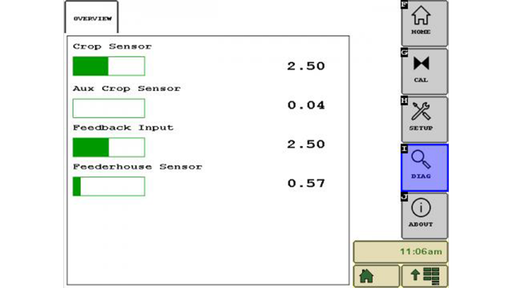

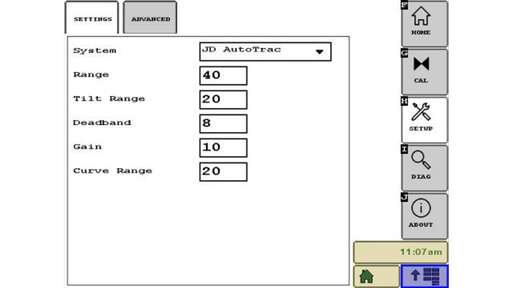

TrueSight allows operators to interface directly from the combine's OEM VT display.

Compatibility

Harvest Loss Report

Using automatic row guidance reduces positioning errors.

A typical corn grower could capture an additional 0.3-0.7 Bu/A in harvested yield compared to manually steering by adding combine row guidance.

TrueSight shows a standard deviation (average error from the center of the row) of 0.5" to 1" while manual steering resulted in a standard deviation of 1.9".

Header loss in these tests more than doubled with only 2" of error from being centered on the row. As expected, the increase in header loss was more significant in the dryer harvest conditions, shown in test #4.

An average operator error of 1" cost 0.3 bu/ac average with a 2" error averaging a loss of 0.7 bu/ac. Errors above 3-5" resulted in significant kernel loss. These effects caused header loss values over 5 bu/acre in tests with greater guidance errors.

I am not sure I would buy a combine without TrueSight. It was a lifesaver for me this year.

Gary

Illinois

Pair With Automatic Height Control

Pair TrueSight with our HeadSight height control system to improve the accuracy and efficiency of your harvest equipment.

TrueSight Product Resources

Download product manuals, software updates, and more.