Key Points

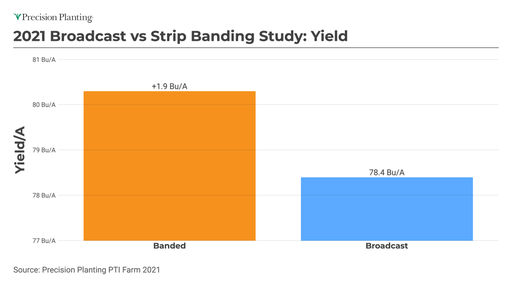

- Objective: To evaluate yield and economics of traditional broadcast applications of dry fertilizer compared to 8" deep high-concentrated strip-till banding of dry fertilizer.

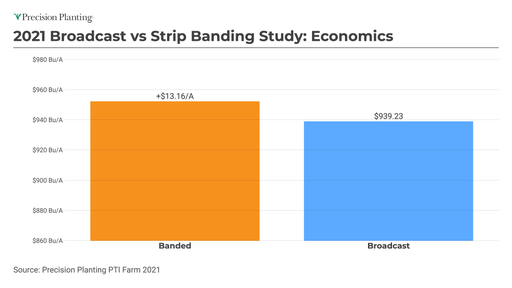

- Economic Increase: There is still much to be seen in this 10-year study, but we have seen economic increases of $30-$51/A by utilizing banded dry fertilizer.

- Tillage Considerations: A major benefit of strip tilling that we have seen is the opportunity to band dry fertilizer at the bottom of the tillage strip.

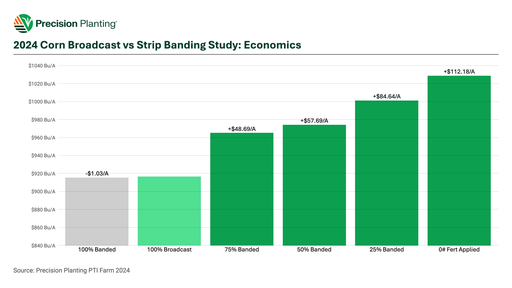

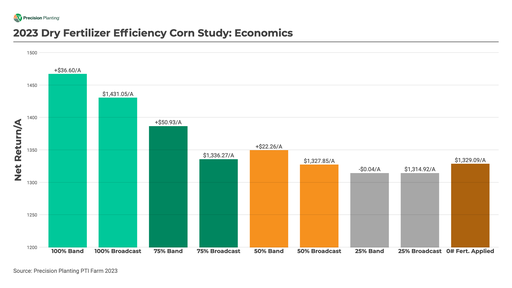

- Upfront Cost: A key recognition in this study is that a higher upfront cost doesn’t inherently mean lower efficiency if there is a significant yield impact.

If we put fertilizer right where the root is, how much more efficient can we be?

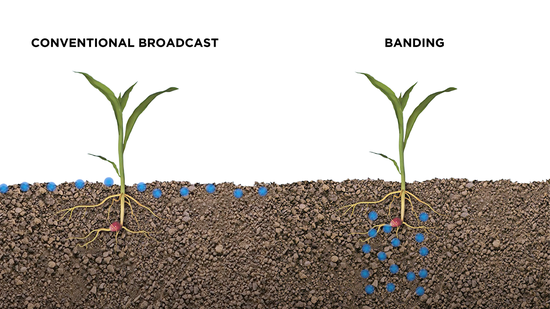

Broadcasting fertilizer is one of the most popular application methods for fertilizer, but what are the agronomic and economic benefits of banding dry fertilizer instead?

Based upon soil test results and yield goals of 250 Bu/A corn in a corn/soybean non-irrigated rotation, a broadcast surface application was made with a traditional spinner truck. Using the same fertilizer rates, a strip-till bar was used to place fertilizer in high concentrated strips 8” deep on 30” corn rows. Corn was then planted directly into the strips above the 8” fertilizer placement. A KUHN Krause Gladiator® pulling a Montag® Gen II 2208 fertilizer cart was used to implement this testing program for 2023 and 2024.

It’s no secret that liquid fertilizer is typically more expensive upfront than dry fertilizer, which is why comparing both banded and broadcast fertilizer applications is the key part of this study.

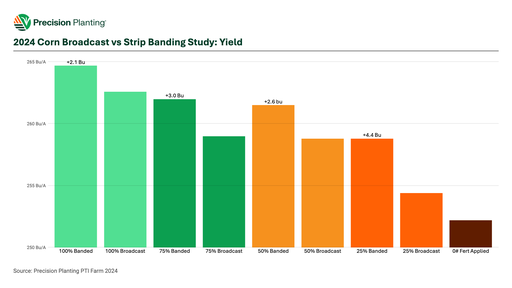

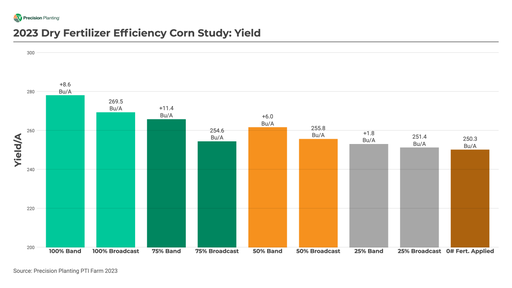

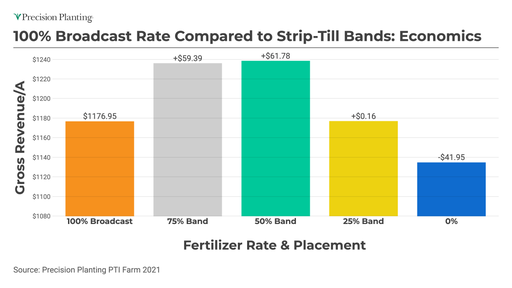

Through 2024, banded fertilizer continued to outperform broadcast at every efficiency rate. In 2023, 100% rates offered a +8.6 Bu/A yield increase, 75% at +11.4 Bu/A, 50% at +6.0 Bu/A, and 25% at +1.8 Bu/A. In 2024, 100% rates offered a +2.1 Bu/A yield increase, 75% at +3.0 Bu/A, 50% at +2.6 Bu/A, and 25% at +4.4 Bu/A.

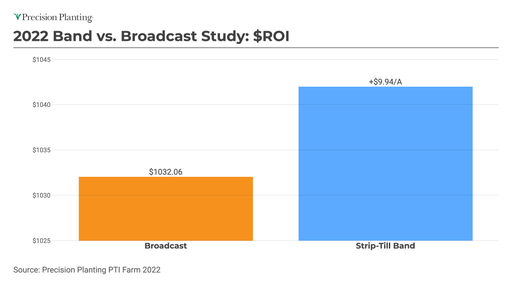

Using University of Illinois Machinery Cost Estimates (shown below), strip-till resulted in additional costs of $9.60/A in comparison to a conventional tillage program. Using this cost scenario, this led to net revenue gains in 2023 of +$36.30/A at 100% banding and +$50.93/A at 75% banding. The lowest rates of 50% and 25% offered net revenue gains at +$22.26/A and -$0.04/A respectively.

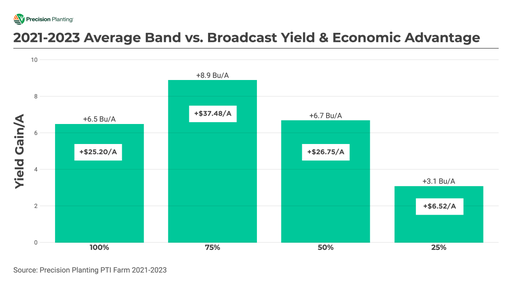

When we look at multi-year data from 2021-2023, we see that banded dry fertilizer has resulted in the highest average yield gains at the 75% fertilizer rate, while 100% and 50% offer average gains of +6.5 Bu/A and +6.7 Bu/A respectively. Reduced rates of 25% offered the lowest gains of the study at +3.1 Bu/A. Looking at average economics, the 75% rate has offered the highest net returns at +$37.48/A.

In-Depth Study Videos

InsidePTI S3•E11

Band vs. Broadcast Fertilizer ‣ Corn

InsidePTI S4•E07

Strip Till Liquid vs. Dry Fertilizer

InsidePTI S2•E32

Banding vs Broadcast

Study Details

Study data collected 2020-2024 at the PTI Farm in Pontiac, IL.

| Planting Date | Varied By Year | Rotation | CAB |

| Row Width | 30” (2021-2024) & 20” (2020) | Population | 36K-36.5K |

| Corn Prices | 2024 - $4.08 2023 - $5.31 2022 - $6.00 2021 - $5.00 2020 - $3.75 | Hybrid | 2024 - DKC 66-17RIB 2023 - DKC 66-17RIB 2022 - DKC 59-82 2021 - DKC 65-95 2020 - GH 10D21, 10L16 |

Related Tags