Fix the Issues Caused by Your Planter

Getting a well-emerged stand of cotton is imperative to getting both yield and quality at harvest; but, current planting equipment limits a cotton seed’s ability to emerge well. The Cotton Planting System from Precision Planting ensures that your seed population, depth, and the environment the seeds are placed in is perfect, allowing each seed to emerge, grow, and thrive. You’ll have cotton fields that are consistent and you’ll be proud each time you drive by them. Upgrade your planter one product at a time or outfit your planter with the full cotton system at once.

Seed Firmers

One of the easiest and most cost-effective swaps on a planter is new seed firmers. Keeton Seed Firmers are a simple planter upgrade. They ride in furrow behind the seed tube to press the seed to the bottom of the furrow. This process ensures good seed-to-soil contact to tuck your valuable seed into moisture with no air gap.

"When our cotton started to emerge, we knew the Keetons were responsible for the most consistent and even stand of cotton we’ve had."

Jonathan Evans, cotton grower in North Carolina

Closing System

Consistent emergence is imperative for high yield and quality in your cotton crop. There’s a familiar struggle of setting a closing system each time a planter enters a new field; if conditions in the field change, all those settings matter. Factory closing systems have limited ability to get closing set right.

FurrowForce is a two-stage closing system with which growers across the Cotton Belt experience great success. It closes the furrow from the bottom up to remove air pockets and firms the soil above the seed to retain available moisture, giving each seed the best chance to germinate.

"When we were ready to upgrade closing systems, my local Precision Planting Premier Dealer invited me out to the field to watch a local farmer plant using various closing wheels, side-by-side. For me, it was a no-brainer. The ability to see them in action in the field next to one another proved that the FurrowForce closing system far exceeded the performance of the others."

Todd Westerfeld, cotton grower in Texas

Seed Meters & Drive System

Getting a consistent stand without overspending on seed is also important. The target population should be the same as the number of seeds going in the ground. Traditional seed meters need continual adjustment to plant accurately which leads to skips, doubles, and ultimately, lost yield.

The solution? Upgrade to vSet meters. The simple design does not require adjustments, is incredibly accurate and easy to maintain. vSet seed meters singulate seeds accurately, resulting in perfect seed placement throughout your field. Meters are the perfect place to start when upgrading your planter.

"The most important pass of the entire year is with the planter. It's worth it. You're going to get a return on investment every single year, every single acre that you go across. You're doing a better job."

Philip Marek, cotton farmer in Southeast Texas

vSet is the most accurate meter in the industry, as evidenced by many planter manufacturers beginning to use it as their factory installed meter. But it is just the starting point. vDrive can be added to the meter to provide maintenance free electric drive. vSet meters + vDrive allow you to have a stress free planting season making sure that your singulation, population, and drive system are working correctly.

On a 16-row planter, there are at least 216 parts that make up a traditional ground drive system. That’s a lot of bearings, sprockets, chains, idlers, and tensioners that could go bad and need to be maintained every year. Even with good maintenance, there are still issues that can come up during planting.

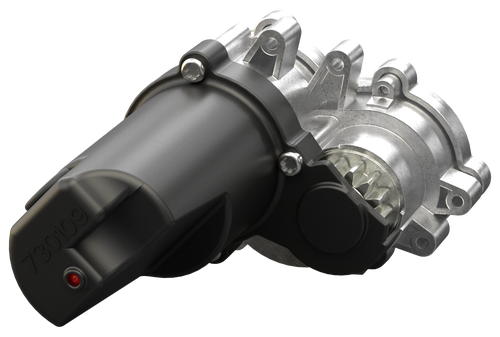

vDrive is a low-maintenance, electric drive system that lets you breeze through planting without the headaches of a mechanical drive system. Go from 13 parts to just 1, simplifying your planter. Through a 20|20 monitor you can visualize the health of each individual vDrive motor, giving you peace of mind that each row is running at its best.

With the vSet meter and vDrive motor combined, prepare to save on inputs and prevent over-planting.

» Learn more About vDriveDownforce

Whether caused by soil type, drainage, residue or field conditions, row-to-row variability exists in every field. Manually set downforce systems cannot adapt to those variations. A single setting across the planter on airbags or springs will not ensure consistent downforce throughout a field. Inconsistent emergence is the result of an incorrectly set downforce system.

DeltaForce can handle field variability. Its row-by-row, automatic control adapts to whatever conditions a row unit encounters to ensure the proper downforce is applied or removed to get the seed to the appropriate depth with minimal compaction. DeltaForce takes the guesswork out of downforce management, making it easier on the operator and saving time in the field.

» Learn More About DeltaForceFind a Precision Planting Premier Dealer