Harvest

Solutions

Data Drives Decisions

With real-time yield by hybrid reports, wireless data sharing between combines, and a Grain Property Kit to keep the system accurate, YieldSense paired with the 20|20 gives you the tools you need for better decisions at harvest and beyond.

1

20|20

Get real-time data from your combine with the 20|20 system paired with YieldSense. One simple calibration per crop, per season, is all you need to get started.

2

YieldSense

YieldSense changes the way grain flow is measured. Our patented flow sensor is installed in the correct location, so accurate yield is measured across all mass rates.

3

Panorama

Once you have harvest data loaded into Panorama it's easy to compare and contrast planting and harvest metrics to make informed decisions for the next growing season.

Automatic Header Height & Tilt Control

Maintaining header height control across the field is difficult. HeadSight automatic header height control is accurate and versatile, giving you the ability to focus on other details that matter.

HeadSight for Corn

Accurate height control creates a more consistent ratio of stalk left standing to residue on the ground, which impacts soil warming and residue management, preparing a better seed bed for planting.

HeadSight for Grain

With automatic header height and tilt control, you can maximize your crop's harvest with minimum stress. Let HeadSight do the calculating and adjusting for you with three styles of poly arms to accommodate different headers and ground conditions.

Increase Your Row Guidance Accuracy

Automatic steering control for your corn header keeps you on track, even through poor visibility, sloping terrain and down corn with our row guidance solutions.

1

Decrease Operator Fatigue

With the assurance of your corn header staying on track, you can focus on other vital settings in the cab. Capture maximum yield with less stress using row guidance.

2

Double the Accuracy

Our flexible, poly sensor feels for two rows instead of the standard single-row detection. This greatly improves accuracy and response, especially in challenging conditions.

3

Increase Productivity

Accurate row guidance can significantly improve material flow and feeding into the header, reducing snout damage and increasing harvest speeds in down corn.

TrueSense

TrueSense adds accurate sensing capabilities to improve your OEM combine's steering controls to capture more yield and reduce operator fatigue while harvesting corn.

TrueSight

TrueSight keeps you harvesting right on the row with a constant touch to the crop by directly controlling the steering valves or the steering motor for maximum control.

Research

Harvest Loss Report

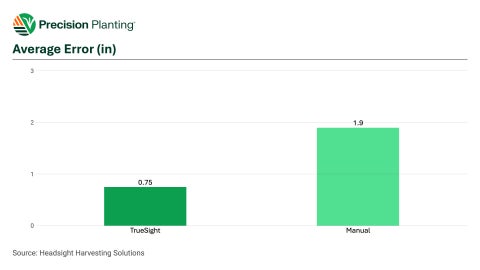

A typical corn grower could capture an additional 0.3-0.7 Bu/A in harvested yield compared to manually steering by adding combine row guidance. TrueSight shows a standard deviation (average error from the center of the row) of 0.5" to 1" while manual steering resulted in a standard deviation of 1.9".

Mix and Match Brands

Trying to pair different brands of combines and headers?

Conversion Kits

It can be difficult to pair unmatched combines and headers together. Conversion kits provide solutions for various combinations of combines and headers, regardless of age or brand, so you aren't limited on the type of harvest equipment you can own.

» Conversion KitsHarvesting Upgrades

Make improvements to your combine with solution kits from Precision Planting, such as a MacDon tilt kit and AGCO hydraulic kit, available for select makes and models.

» Harvesting Upgrades