Written by: Emily Ponwith

Ryan and Emily Ponwith are sixth-generation corn and soybean farmers in south-central Minnesota. With professional backgrounds in agronomy and education, the two of them are passionate about not only continually improving their farming practices, but educating other growers & consumers about modern farming practices. Emily shares her perspective from the farm on Instagram @emilyponwith and blogs at emilyponwith.com. You can follow along with their farm on Facebook @PonwithFarms.

Making the decision to upgrade equipment is typically not one that is taken lightly. It is rarely an overnight decision and often comes with a tremendous amount of number crunching and analysis on how this will improve not only efficiency, but ROI as well. Our farm purchased a used 2010 16-row 1770NT John Deere planter in 2014. It was time for our farm to upgrade the width of the planter and explore technology to improve planting efficiency. Obtaining consistent seed size was something that we were struggling with at the time due to tough growing conditions in various seed regions, something out of our control. However, what we could control was the technology and systems on our planter to allow it to perform the best regardless of the seed size.

After getting our new-to-us planter home we added vSet, vDrive, DeltaForce, and CleanSweep before spring planting. On our previous planter, we had CleanSweep, and we were not willing to go without that.

“SmartFirmer provides some really unique information that I feel like gets under utilized by a lot of growers. It helps manage a clean furrow and helps to ensure that you are planting into moisture. I use it all of the time.”

Ryan Ponwith, farmer and agronomist

Minnesota

The first spring with our planter was very damp and cold. Due to adverse conditions, we are confident that just the investment in DeltaForce alone paid for the entire planter retrofit with the conditions we were faced with. Our crop still came up with relatively uniform emergence despite the tough planting conditions.

Needless to say our first year with the planter and the retrofit decisions we made blew us away. The following year we added Keeton Seed Firmers and the year after that we added SmartFirmer. What is unique about Precision Planting technology is that you don’t have to do it all at once, you can pick and choose what the most critical issues are on your farm and address those first.

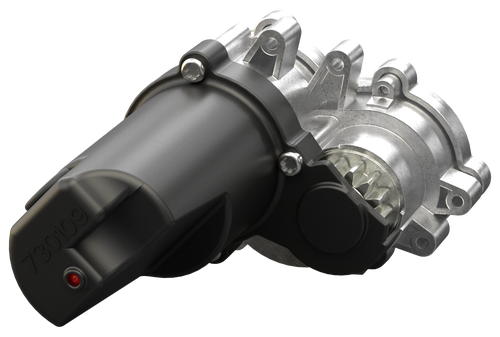

FurrowForce, a 2-stage closing system, was added to our planter when it was released. As a no-till and strip-till operation, adding this technology was a no-brainer. We have two wildly different planting environments that we are working with each year. Our corn ground is strip tilled and when we added FurrowForce our soybean ground was no-till. Since then we have started vertical tillage on our soybean ground.

FurrowForce technology has been a total game changer as we manage planting across many different tillage environments. It allows us to manage our seed to soil contact in the strips, and in the no-till, FurrowForce helps to close the trench in varying planting conditions. We ordered our FurrowForce system at a time when there was a shortage of sensors needed to control it automatically. Our system is manually controlled, and we intend to add automatic control sometime in future. We look forward to seeing the difference in how FurrowForce reacts autonomously to the varying soil types and layers to be sure we are always closing the seed trench appropriately. Making seemingly small adjustments over the years has made a big difference on our return.

On the Horizon

We are planning to add Reveal in the near future. We feel that mounting the row cleaners to the frame instead of the row unit will be huge for us to improve our spacing and our good ride. With our fall strips, sometimes getting a good ride and good spacing can be challenging and we feel that adding Reveal to our planter could greatly enhance performance. We are looking forward to this addition to our planter when the time is right.

We’d like to upgrade from a Gen 2 monitor to a Gen 3 20|20 monitor and would also like to add SpeedTube. We will likely look at upgrading our entire planter for something wider before making those upgrades. When that time comes we plan to upgrade all of our existing Precision Planting technology as well, once you make the investment and see the difference it makes in the planting environment you won’t ever go back.

Intuitive to Install & Maintain

Prior to making our initial investments, we sat down with our Premier Dealer for Precision Planting. We had a thorough conversation with him about the planter we wanted to retrofit and what components would best fit our immediate needs and budget.

When the parts arrived we did all of the installation ourselves. The instructions from Precision Planting are very well thought out and intuitive to follow. Our Premier Dealer was just a phone call away with any questions that arose in the process. They do offer installation services, but we had the time and desire to do it ourselves and plan to continue to self-install in the future. Having the ability to install the technology ourselves gave us a deeper understanding of how the components work together, that way when something arises we know where to look.

Maintaining our Precision Planting technology is ongoing, as with anything on the farm. We work with our dealer during the off-season to secure parts. Our dealer allows us to keep extra wear parts on hand that may fail throughout the season or wires that may break, so we can make a quick fix if needed. At the end of the planting season we are able to return what we don’t use to our Premier Dealer. We are 45 minutes one-way from our dealer, so this is a huge time saver for everyone involved. The customer service that we receive on our Precision Planting technology is unmatched.

Every year or two we bring our meters into our Premier Dealer to put them on a MeterMax. They test each meter for performance and make necessary adjustments to make sure everything is performing to the best it can.

Ultimately, you only get 30-40 crops to put in throughout your career. That may even be a stretch for some growers. If you want to make sure you are doing it right, Precision Planting makes products you can trust to create an integrated planter system that you can trust year after year.